Precision in manufacturing is essential for maintaining product integrity and operational efficiency. One of the most crucial components in achieving this precision is the use of high-quality ground bars. These bars are a foundational material in industries ranging from aerospace to automotive and medical equipment manufacturing. In a city like Chicago, known for its robust industrial and manufacturing sector, the demand for reliable materials is higher than ever. Our blog explores why high-quality ground bars are vital for manufacturing excellence and how they contribute to superior performance in various applications.

Why High-Quality Ground Bars Matter in Manufacturing

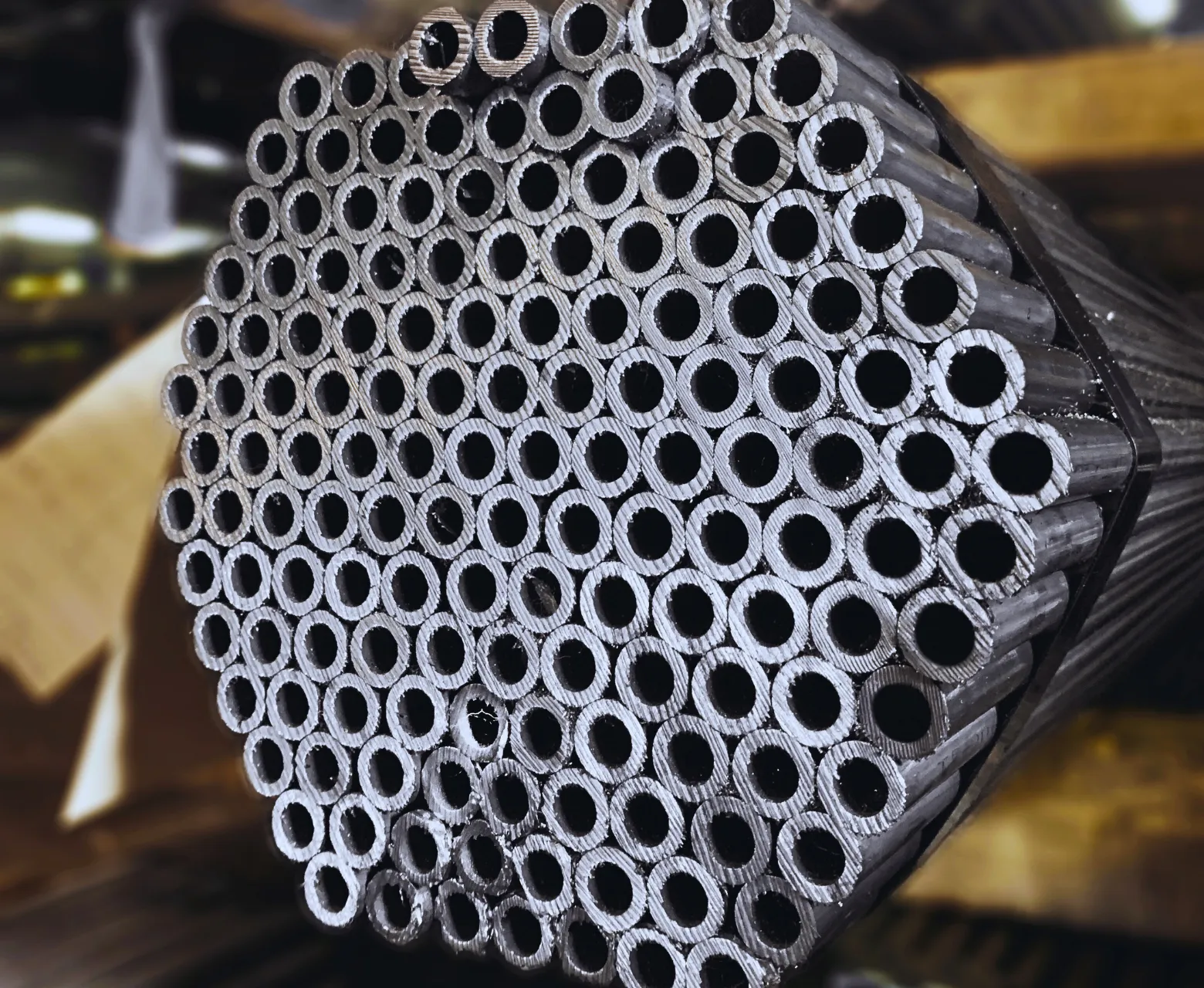

Precision is key in any manufacturing process, and high-quality ground bars ensure that components fit seamlessly into complex machinery and structural frameworks. These bars undergo a specialized centerless grinding process, resulting in a perfectly smooth surface and precise dimensions. When manufacturers in Chicago rely on inferior materials, they risk defects, inefficiencies, and increased production costs.

The ability to maintain tight tolerances is a primary reason high-quality ground bars are preferred. Their exceptional roundness and straightness enhance machining efficiency, reducing wear on cutting tools and leading to more accurate final products. Moreover, these bars improve the overall strength and durability of manufactured parts, ensuring long-term reliability.

The Role of Ground Bars in Chicago’s Manufacturing Industry

Chicago has long been a hub for manufacturing, hosting a diverse range of industries that depend on high-performance materials. From advanced machinery and automotive components to structural frameworks in construction, high-quality ground bars play a significant role in production.

Local manufacturers understand the need for precision and durability, which is why they source ground bars from reputable providers like Precision Ground Bars. The demand for these materials spans multiple sectors, making it essential for businesses to invest in superior-quality bars to maintain their competitive edge.

The Centerless Grinding Advantage for High-Quality Ground Bars

One of the most critical processes in producing high-quality ground bars is centerless grinding. This technique ensures that the bars have uniform diameters, exceptional straightness, and a refined surface finish. Unlike traditional machining methods, centerless grinding removes material evenly from the bar’s surface without the need for a fixed centre point.

This results in:

- Increased efficiency in production and reduced lead times.

- Improved surface quality, minimizing friction and wear in applications.

- Greater dimensional accuracy, leading to seamless integration into high-precision machinery.

For manufacturers in Chicago, investing in centerless ground bars ensures that their end products meet strict industry standards without costly material waste or rework.

The Benefits of Bar Straightening and Chamfering Services

To further enhance the performance of ground bars, additional finishing services such as bar straightening and bar chamfering play a crucial role. Bar straightening corrects any minor deviations in shape, ensuring that bars maintain optimal alignment for machining and assembly processes. This is particularly important for industries that require extreme precision, such as medical and aerospace manufacturing.

Meanwhile, bar chamfering refines the edges of the bars, removing sharp corners to prevent damage during handling and improve safety in the manufacturing process. Chamfered bars also facilitate smoother transitions in mechanical applications, reducing stress concentration points that can lead to premature wear or failure.

How Precision Ground Bars Meet the Needs of Chicago’s Manufacturers

Manufacturers in Chicago looking for the highest quality materials should partner with trusted suppliers who understand their specific industry needs. Precision Ground Bars provides expertly crafted materials that support efficient production processes. Their services include:

- Bar Chamfer for improved safety and usability.

- Centerless Grinding Service for high-precision finishing.

- Grinding Services to achieve the perfect dimensional tolerance.

- Bar Straightening Services to correct imperfections and enhance usability.

By ensuring strict quality control and utilizing advanced grinding techniques, Precision Ground Bars delivers materials that meet the highest industry standards, allowing Chicago’s manufacturers to enhance their production capabilities.

Conclusion

The importance of high-quality ground bars in manufacturing cannot be overstated. These essential materials improve product precision, durability, and efficiency across multiple industries in Chicago. From advanced grinding techniques like centerless grinding to crucial finishing services such as bar straightening and bar chamfering, investing in premium ground bars ensures that manufacturers achieve the highest level of performance in their operations.

For businesses looking to enhance their manufacturing processes, choosing a trusted provider like Precision Ground Bars is a step toward operational excellence. Contact us to learn more about how superior ground bars can transform your production quality.

FAQs

What are high-quality ground bars used for?

High-quality ground bars are used in various industries, including aerospace, automotive, medical devices, and construction. Their precise dimensions and smooth surfaces make them ideal for applications requiring tight tolerances and structural integrity.

How does centerless grinding improve the quality of ground bars?

Centerless grinding removes material evenly, resulting in a perfectly round and straight bar with a refined surface. This process ensures dimensional accuracy and reduces the need for additional finishing, making it highly efficient for precision manufacturing.

Why is bar straightening important?

Bar straightening ensures that ground bars maintain optimal alignment, reducing issues during machining and assembly. This process is crucial for industries requiring extreme precision, such as medical device manufacturing and aerospace engineering.

What benefits does bar chamfering provide?

Bar chamfering removes sharp edges from ground bars, enhancing safety during handling and improving usability in mechanical applications. It also helps reduce stress concentrations that can lead to material failure.

Where can manufacturers in Chicago find high-quality ground bars?

Manufacturers in Chicago can source premium ground bars from Precision Ground Bars, a trusted provider specializing in centerless grinding, bar straightening, and chamfering services to meet high industry standards.